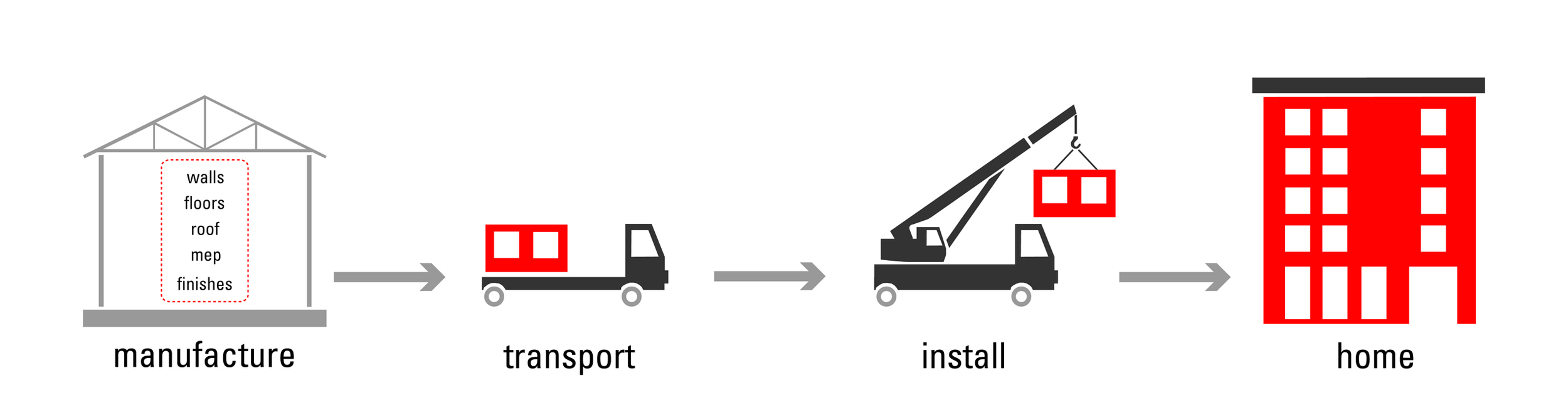

Many misconceptions surround the delivery method of modular building. Outside the modular building industry people are familiar with Structurally Insulated Panels (SIPs) or the ubiquitous mobile homes. In contrast, the way we will use modular construction will be completely indistinguishable from site built construction. Kirkland Avenue Townhomes will be built of a system of fully finished module blocks, about the size of a shipping container, that are replete with all finishes, plumbing, toilets, windows, etc. These modules are delivered to the site, craned into place, strapped together, and then the roofed in a matter of weeks.

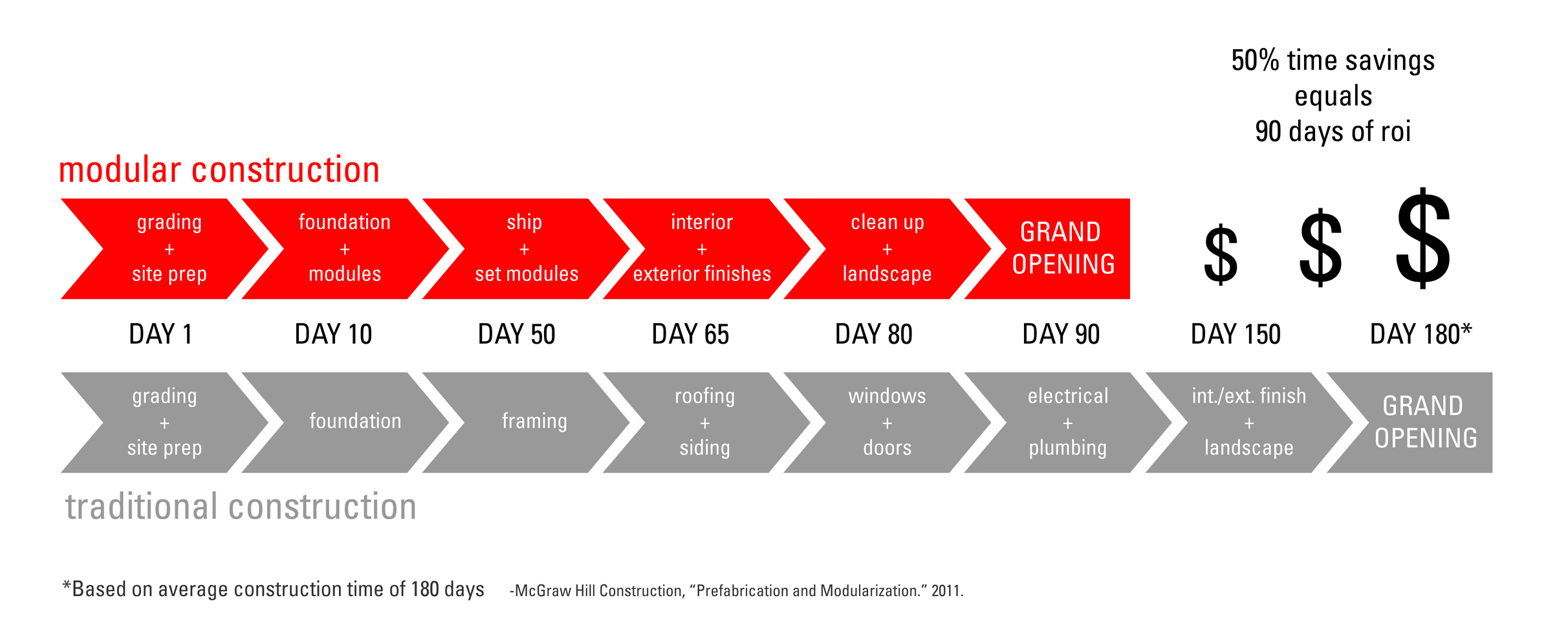

Building projects modularly has its advantages over site built construction. The factory environment eliminates outside elements, minimizing rain and water damage, as well as the mold and health issues that can accompany them. It holds the potential to speed up construction since disparate trades can work concurrently. For instance, currently on site in Renton, Pavilion Construction, the General Contractor, is finishing up the foundation while Champion Homes, our Modular Subcontractor, is framing and plumbing walls. This overlap can shorten construction time which not only reduces costs of construction but allows the Renton Housing Authority to place tenants faster.

Champion Homes has developed a very efficient process in their factory line. The floor of the module moves continuously from bottom left up, when it is craned onto rollers where it moves down the line. Other elements, such as the walls and the ceiling are framed alongside the line, and craned onto the floor as they are finished. Many processes are different from standard construction, since there is no concern of weather affecting, or damaging, interior finish materials, work that typically must wait for the building to be dried-in happens concurrently to structural framing. This not only changes sequencing, but also changes how details are executed.